Iv and pharmacological application

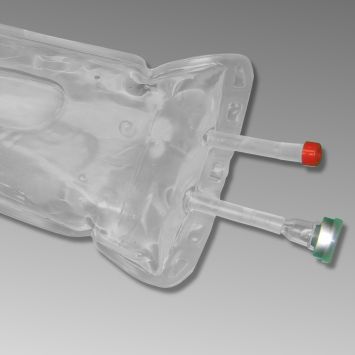

The flexible IV bag provides many advantages compared to the common glass bottle or blow molded plastic container. It is light, easy to handle, carry and store and – most important – collapsible which makes air vents redundant. Further advantages are the reduction of weight and volume and a high level of transparency.

PolyCine’s polyolefin based APP-series provides high-quality and cost effective film and tubing solutions for many different applications.

The tailor-made films come as three-layer coextruded tubular films or cut as double wound flat film in customized widths.

|

APP-114-S

|

|

|

APP-114-G

|

|

|

APP-114-E

|

|

|

APP-107 (Tube) For polyolefin based IV bag and filling tubes our APP107 is a high class material. The tubes are easily weldable and adhere with ports made of polycarbonate and polypropylene during autoclavation.

|